Enquiry

We appreciate each customer and we are proud that 60% of clients come back to work with us again.

Cable Trays ensure that this support function is adequately performed. The trays are supported at regular intervals enabling appropriate loading in accordance with requirements of standards.

In a building environment, cables need to be run from the main distribution board to sub main boards. In order to ensure safe transportation and distribution of cables it is essential to use an appropriate cable support system.

Cable Trays ensure that this support function is adequately performed. The trays are supported at regular intervals enabling appropriate loading in accordance with requirements of standards.

The choice of products and nish depends on atmospheric conditions and the capability of the support system to withstand adverse conditions.

Altair cable trays offer a high degree of exibility, both from a perspective of locating the component parts to accessing the cable supports. The cable trays are available in various nishes including pre-galvanised, galvanised after manufacture and epoxy coated finishes and various grades of stainless steel. Altair cable trays and ladders comply to the requirements of the BS EN6153722001.

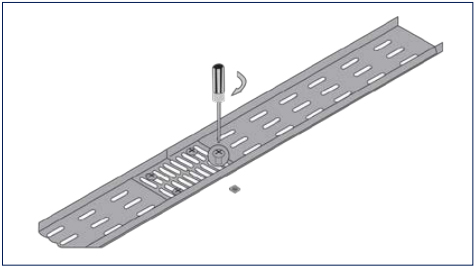

The usage of accessories will ensure that the client is delivered a proper solution, complete with component parts. This will also reduce the need to cut on-site and, risks associated with the onset of resultant corrosion. If the need arises to cut product onsite, it is recommended to apply a layer of cold galvanizing paint on the cut surface /edges after the rough edges have been filed off.

| Materials | Finishes Available |

|---|---|

| Pre-galvanised to BS EN10142:1993 | Original Finish |

| Hot Rolled Sheet Steel to BS EN 10111:1998 | Hot Dip Galvazed to BS 729:1971 |

| Electro Galvanised Steel to BS EN 10152:1994 | Epoxy Coated |

| Hot Rolled Sheet Steel to BS EN 101111:1998 | Hot Dip Galvazed to BS 729:1971 and epoxy coated |

| Stainless Steel Grade AISI 304, 316 or 316L | Original Finish |

In humid / salt laden conditions, it is recommended to use products that have been galvanised after manufacture. This will reduce the chances of product failure in such conditions. In extremely corrosive surroundings, stainless steel containment is recommended, as this has the capability to withstand such conditions. For non exposed corrosive areas such as sewage treatment plans, the usage of non metallic containment is recommended.

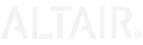

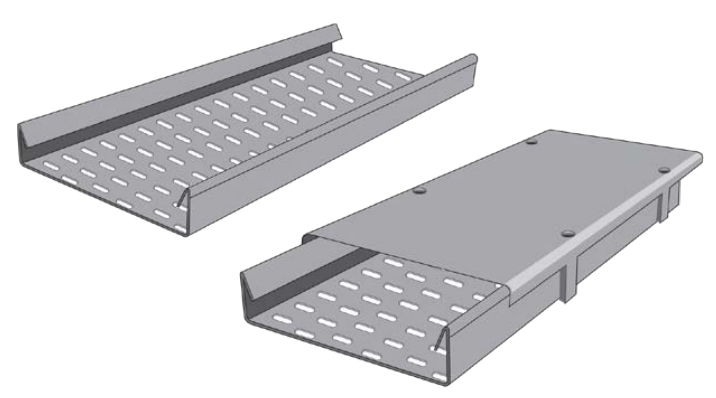

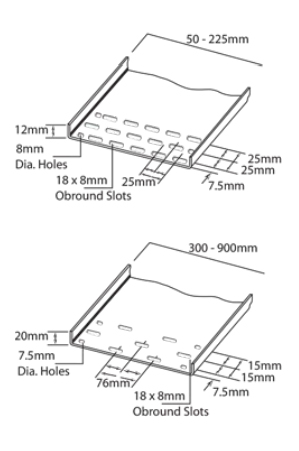

Light Duty Cable Trays:

Length: 3 Meters

Flange Height

For widths ranging from 50mm to 100mm: 15mm

For widths ranging from 150mm to 600mm: 25mm

Heavy Duty Cable Trays:

Length: 3 Meters

Flange Height

For all widths: 50mm

Return range: 12mm (25mm available on request)

90° Flat Bend

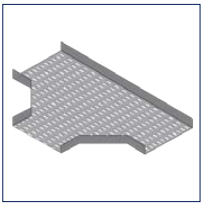

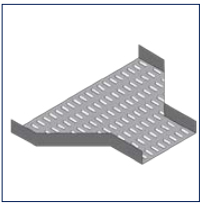

Equal Tee

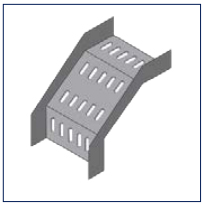

90° Outside Riser

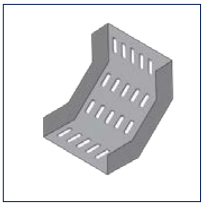

Inside Riser

Reducer

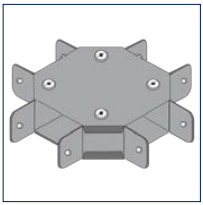

4 Way Cross

90° Flat Bend

90° Flat Bend

90° Flat Bend

90° Flat Bend

| Width (mm) | Gauge (mm) | Trays | Flat Bend 90 degree | Flat Equal Tee | Cross | Inside Riser 90 | Outside Riser 90 |

|---|---|---|---|---|---|---|---|

| 50 | 1.0 | AHT/50 | AHT/90B/50 | AHT/ET/50 | AHT/X/50 | AHT/90IR/50 | AHT/900R/50 |

| 75 | 1.0 | AHT/75 | AHT/90B/75 | AHT/ET/75 | AHT/X/75 | AHT/90IR/75 | AHT/900R/75 |

| 100 | 1.0 | AHT/100 | AHT/90B/100 | AHT/ET/100 | AHT/1X/00 | AHT/90IR/100 | AHT/900R/100 |

| 150 | 1.2 | AHT/150 | AHT/90B/150 | AHT/ET/150 | AHT/X/150 | AHT/90IR/150 | AHT/1900R/50 |

| 225 | 1.2 | AHT/225 | AHT/90B/225 | AHT/2ET/25 | AHT/X/225 | AHT/90IR/225 | AHT/2900R/25 |

| 300 | 1.5 | AHT/300 | AHT/90B/300 | AHT/ET/300 | AHT/3X/00 | AHT/90IR/300 | AHT/900R/300 |

| 450 | 1.5 | AHT/450 | AHT/90B/450 | AHT/ET/450 | AHT/X/450 | AHT/90IR/450 | AHT/900R/450 |

| 600 | 2.0 | AHT/600 | AHT/90B/600 | AHT/ET/600 | AHT/X/600 | AHT/90IR/600 | AHT/6900R/00 |

| 750 | 2.0 | AHT/750 | AHT/90B/750 | AHT/ET/750 | AHT/X/750 | AHT/90IR/750 | AHT/900R/750 |

| 900 | 2.0 | AHT/900 | AHT/90B/900 | AHT/ET/900 | AHT/X/900 | AHT/90IR/900 | AHT/900R/900 |

Note: Different thickness and sizes can be made available on request

Please note : AlTair reserves the right to change perforation patterns and product specifications without prior notice